Sort By

All Category Groups

All Brands

All Categories

All Products 22733

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Call us

SIT

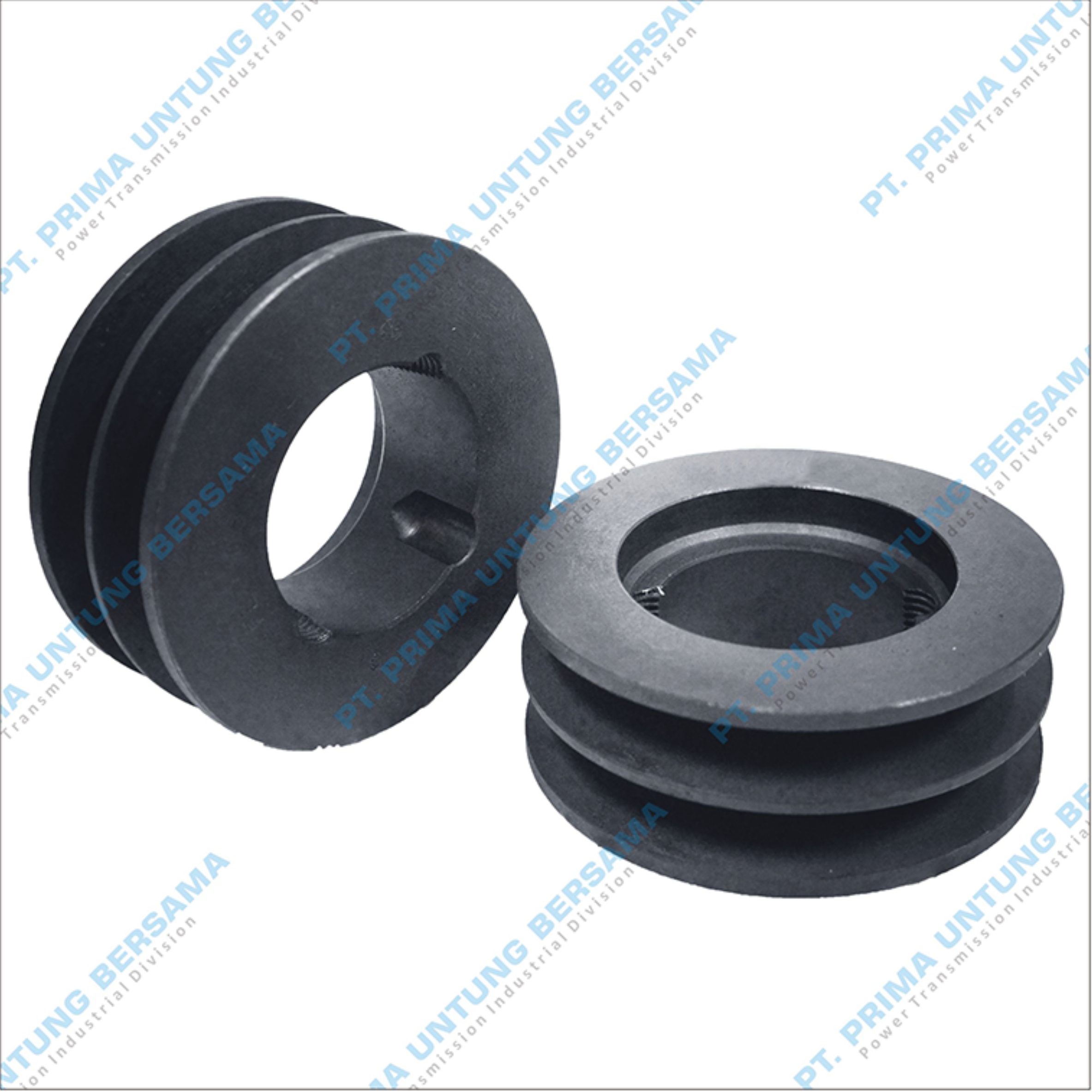

- Taper Bush : 2517

- Shaft Diameter Range : 18 - 65 mm

- Pitch Diameter : 500 mm

- Outside Diameter : 504 mm

- Groove : 2

[Please login to see price]

Ask Quote

Ask Quote

Call us

SIT

- Taper Bush : 3020

- Shaft Diameter Range : 25 - 75 mm

- Pitch Diameter : 500 mm

- Outside Diameter : 504 mm

- Groove : 4

[Please login to see price]

Ask Quote

Ask Quote

Call us

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

Ask Quote

Available

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

Ask Quote

Call us

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

Ask Quote

Available

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

Ask Quote

Available

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

Ask Quote

Available

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

Ask Quote

Call us

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

Ask Quote

Call us

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

Ask Quote

Call us

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

Ask Quote

Call us

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

Ask Quote

Available

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

Ask Quote

Call us

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

Ask Quote

Call us

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

Ask Quote

Call us

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

Ask Quote

Call us

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

Ask Quote

Available

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

Ask Quote

Call us

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

Ask Quote

Call us

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

Ask Quote

Available

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

Ask Quote

Call us

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

Ask Quote

Call us

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

Ask Quote

Call us

STARKZ

Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes. For higher speed is strongly recomended to use steel as material of construction.

Our PBT pulleys are statically balanced according to ISO.

The PT pulleys are not balanced, as they do not have a finished bores.

[Please login to see price]

Ask Quote

.png)

.png)