Sort By

All Category Groups

All Brands

All Categories

All Products 23918

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Call us

[Please login to see price]

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Call us

SIT

- The CLASSICA® synchronous belt, being designed with imperial pitch, is a valid and economical altenative solution in low/medium torque transmission systems.

- Reduced elongation, no need of lubrication and low wearing makes this belt an economic and reliable option.

- How to measure the size of a product :

- For example, CD210L075

- - 210 = pitch length x 10 (inches)

- - L = pitch

- - 75 = belt width x 100 (inches)

[Please login to see price]

Ask Quote

Ask Quote

Call us

SIT

- The CLASSICA® synchronous belt, being designed with imperial pitch, is a valid and economical altenative solution in low/medium torque transmission systems.

- Reduced elongation, no need of lubrication and low wearing makes this belt an economic and reliable option.

- How to measure the size of a product :

- For example, CD210L075

- - 210 = pitch length x 10 (inches)

- - L = pitch

- - 75 = belt width x 100 (inches)

[Please login to see price]

Ask Quote

Ask Quote

Call us

Ask Quote

Call us

Ask Quote

Call us

SIT

- TOP DRIVE® HTD belt is an evolution of standard positive drive belts. The tooth shape is the HTD profile according to ISO 13050.

- This profile has been used for many years in a wide range of applications and it is well known for its outstanding performances. Power transmission is much higher compared to the classic inch trapezodial profile.

- The circular-arc tooth provides superior tooth jump resistance and provides a smooth tooth engagement. The noise level is remarkably reduced if compared to the classic trapezodial belts.

- How to measure the size of a product :

- For example, CHD1064-8M20

- - 1640 = pitch length (mm)

- - 8M = pitch

- - 20 = belt width (mm)

[Please login to see price]

Ask Quote

Ask Quote

Ask Quote

Call us

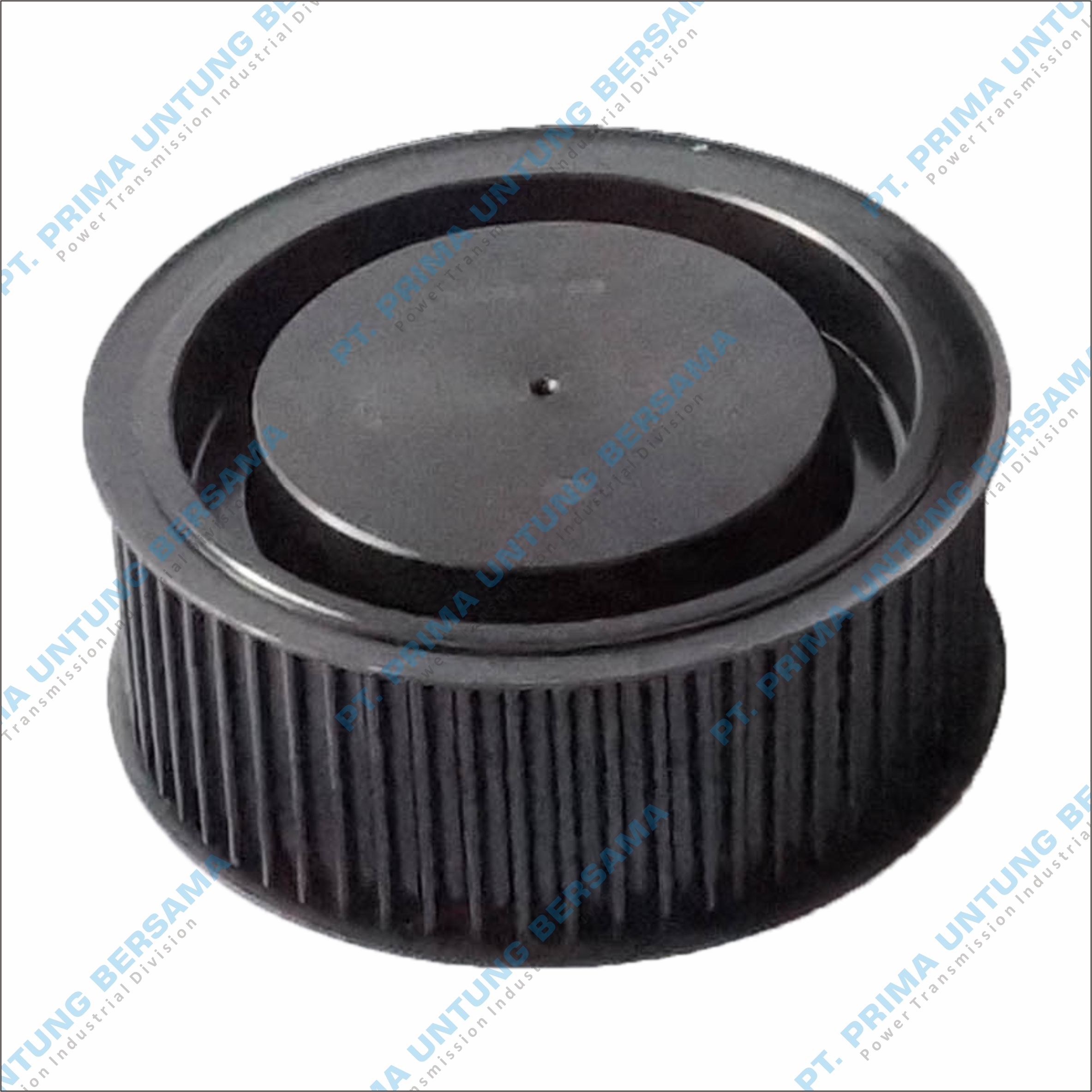

SIT

- Type of belt : S 14 M

- Pitch : 14 mm

- Pitch diameter : 264.59 mm

- Outside diameter + flange : 274 mm

- Teeth : 60

- Belt width : refer to the last number in every product name. (example : ST60-S14M115, so the belt width is 115mm)

- Type of pulley : 8

- Material : Cast iron

- Flange : With flanges

[Please login to see price]

Ask Quote

Ask Quote

Call us

SIT

- SIT-LOCK® locking assembly unit consists of four pieces with two inside double-one rings joined through a set of tightening screws. It is recomended for medium torques. Although it is not self centering, it can be easily assembled and diassembled.

- Here are the dimensions of product :

- Inner Diameter : refer to numbers writen after "F" in every product name. For example, CAL1F20/47; so, the inner diameter is 20 mm.

- Outside Diameter : refer to the last number in every product name. For example, CAL1F20/47; so, the outside diameter is 47 mm.

- High : 90 mm

- Screws : 36

- Type of Screws : M22

[Please login to see price]

Ask Quote

Ask Quote

Call us

SIT

- Locking assembly with single taper design. Provides good concentricity and self centering.

- It is recommended for medium torques and is self-centring.

- The flange design prevents axial movement during installation.

- For the dimension of the product, please download the catalog in the document section

[Please login to see price]

Ask Quote

Ask Quote

Call us

SIT

- SIT-LOCK 14 are shrink discs for external, series "14", are characterised by a single tapered ring instead of opposite tapers of the 3 pieces shrink discs SIT-LOCK series "11". The SIT-LOCK 14 Shrink discs offer a better concentricity and centering and very good balancing. These features make the series highly suitable for mid-high speed applications.

- SIT-LOCK 14 are manufactured in five different types :

- - 14-21 for mid torque transmission

- - 14-22 for high torque transmission

- - 14-81 for very high torque transmission

- - 14-23 eqivalent in size to the type 14-22 but able to transmit an extra 20-30% of torque

- - 14-83 eqivalent in size to the type 14-81 but able to transmit an extra 20-30% of torque

[Please login to see price]

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Call us

Ask Quote

Call us

Ask Quote

Call us

Ask Quote

Call us

Ask Quote

Ask Quote

Ask Quote

Call us

SIT

- TRASCO® ES is our zero backlash coupling designed to compensate for misalignment and vibration dampening for indexing applications. The compact design of TRASCO® ES makes it the right choice for all precise motion applications.

- The TRASCO ES consist of two hubs, which are either made of high-strength aluminium (up to the 38/45 size) or steel (from size 42) that are connected with an elastic element.

- Spider detail

- Color : Yellow

- Shore : 92 Sh.A

- Compound : Polyurethane

- Admissible Temperature [°C] :the range is between -40 and +90°C

[Please login to see price]

Ask Quote

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Call us

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Call us