Sort By

All Category Groups

All Brands

All Categories

All Products 23918

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Call us

SIT

- SIT TAPER LOCK BUSHING is designed to give the following:

- 1. Perfect assembly

- 2. rapid dismantling of the pulley and other transmission equipment

- 3. No special tools requirement except hexagonal key

- The large range of finished bores available ensures that an immediate assembly can be made thus avoiding costly factory down-time.

- Here are the dimensions of Taper Bushing with type 1210 (30.25)

- - Bore : we provide taper bushing with minimal bore 12 mm and 5/8 inches; for the max bore you can look at the number writen after "BC" in every product name.

- for example, BC3025F12 (1210X12MM), so the max bore is 30 mm.

- - Width : the numbers writen in every product name before "F" is width size.

- for example, BC3025F12 (1210X12MM), so the width is 25 mm.

- - Bore size : look at the last number in every product name.

- for example, BC3025F12, so the bore size is 12.

[Please login to see price]

Ask Quote

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Call us

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Call us

Ask Quote

Call us

SIT

Sprocket for chain according to DIN 8187 - ISO/R 606

De : External Diameter mm

Dp : Pitch Diameter mm

Dm : Hub Diameter mm

W : Weight kg

[Please login to see price]

Ask Quote

Ask Quote

Call us

Ask Quote

Call us

SIT

- TOP DRIVE HTD DUAL synchronous belts can be used in a wide range of apllications where one or multiple pulleys are driven by one belt.

- Inside and outside teeth are identical and are located directly in correspondence o each other. they can be used with standard HTD timing pulleys.

- How to measure the size of a product :

- For example, C2HD960-8M50

- - 960 = pitch length (mm)

- - 8M = pitch

- - 50 = belt width (mm)

[Please login to see price]

Ask Quote

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Call us

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Call us

SIT

Sprocket for chain according to DIN 8187 - ISO/R 606

De : External Diameter mm

Dp : Pitch Diameter mm

Dm : Hub Diameter mm

W : Weight kg

[Please login to see price]

Ask Quote

Ask Quote

Call us

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Call us

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Call us

Ask Quote

Call us

SIT

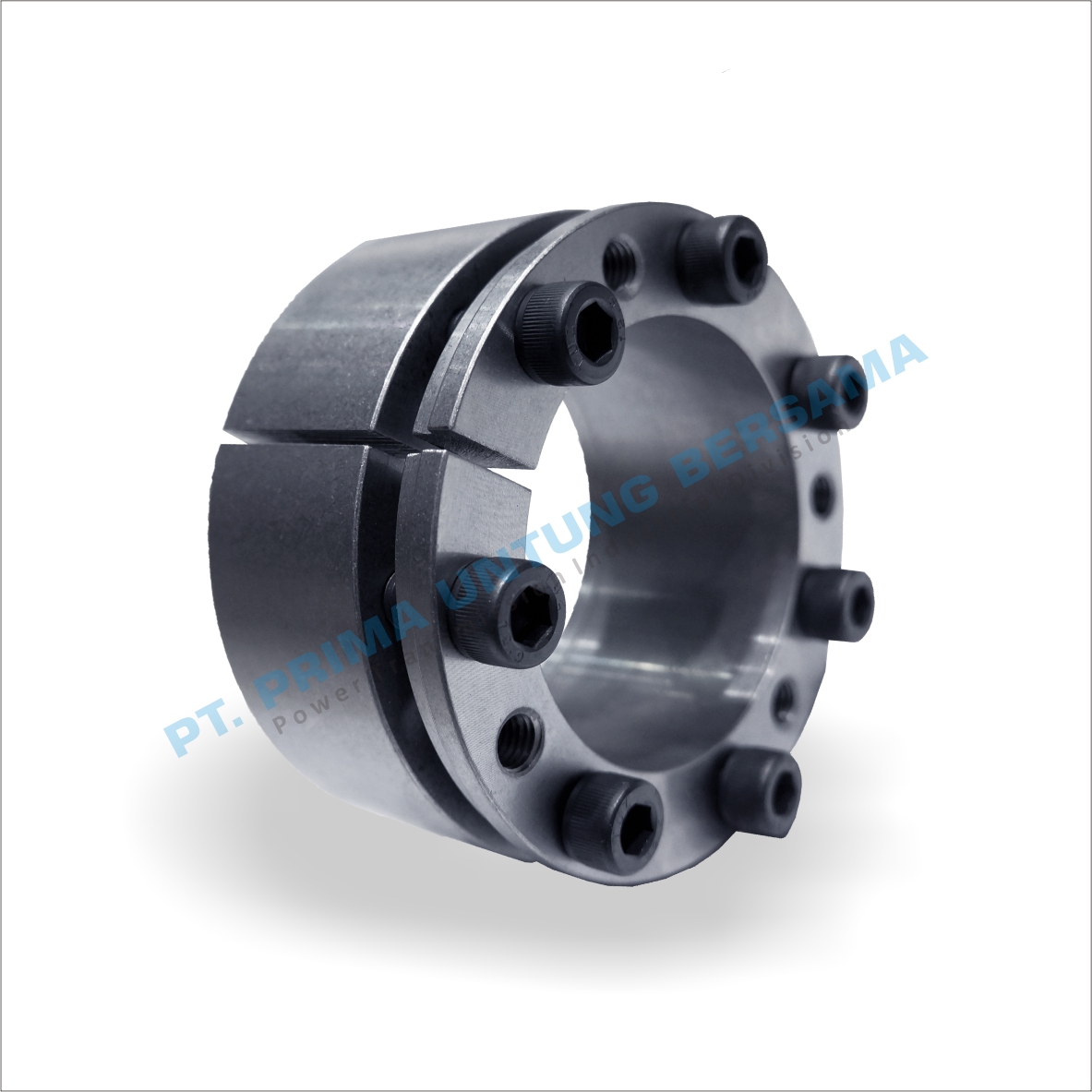

- Locking assembly with single taper design. Provides good concentricity and is self centering.

- SITLOCK® 6 is suitable for applications with medium torques.

- For the dimension of the product, please download the catalog in the document section.

[Please login to see price]

Ask Quote

Ask Quote

Call us

SIT

Sprocket for chain according to DIN 8187 - ISO/R 606

De : External Diameter mm

Dp : Pitch Diameter mm

Dm : Hub Diameter mm

W : Weight kg

[Please login to see price]

Ask Quote

Ask Quote

Call us

Ask Quote

Call us

DIAMOND

Built to ASME / ANSI B29.1 standards for dimensions, interoperability, and sprocket fit, the ASME / ANSI Standard Roller Chain series also meets Diamond Chain’s rigorous internal requirements. From industry to agriculture, our Standard Series chains are designed to fit a wide variety of standard applications, and to last longer than any other manufacturer’s chain.

[Please login to see price]

Ask Quote

Ask Quote

Call us

SIT

- Locking assembly with single taper design. Provides good concentricity and is self centering.

- SITLOCK® 6 is suitable for applications with medium torques.

- For the dimension of the product, please download the catalog in the document section.

[Please login to see price]

Ask Quote

Ask Quote

Call us

SIT

Sprocket for chain according to DIN 8187 - ISO/R 606

De : External Diameter mm

Dp : Pitch Diameter mm

Dm : Hub Diameter mm

W : Weight kg

[Please login to see price]

Ask Quote