Sort By

All Category Groups

All Brands

All Categories

All Products 23934

Ask Quote

Ask Quote

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Call us

[Please login to see price]

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Call us

[Please login to see price]

Ask Quote

Call us

[Please login to see price]

Ask Quote

Call us

Ask Quote

Call us

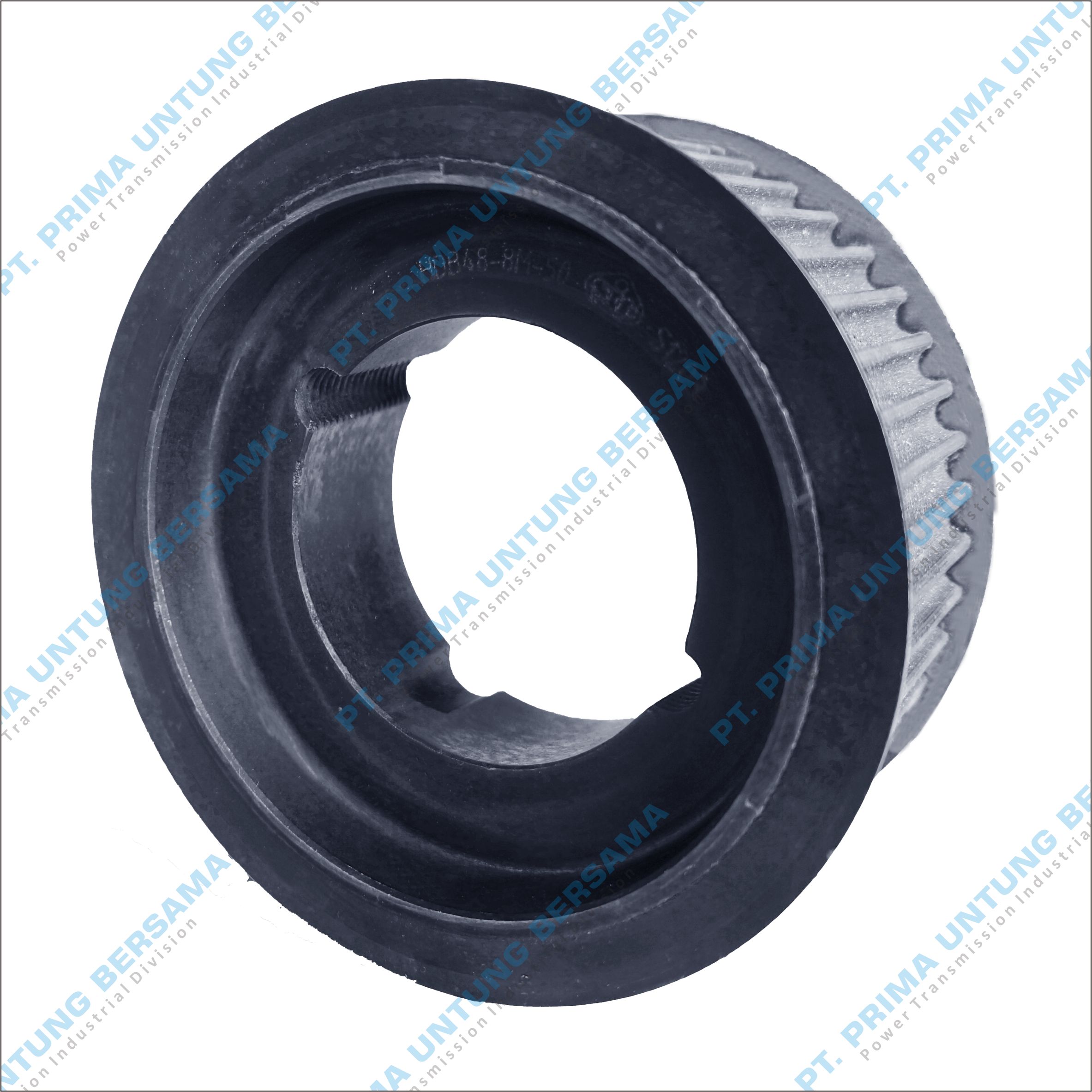

SIT

- Type of belt : 8 M

- Pitch : 8 mm

- Pitch diameter : 426.42 mm

- Outside diameter + flange : -

- Teeth : 168

- Type of bush : 3020

- Belt width : 50 mm

- Type of pulley :14

- Material : Cast iron

- Flange : Without flanges

[Please login to see price]

Ask Quote

Ask Quote

Call us

Ask Quote

Call us

DIAMOND

Built to ASME / ANSI B29.1 standards for dimensions, interoperability, and sprocket fit, the ASME / ANSI Standard Roller Chain series also meets Diamond Chain’s rigorous internal requirements. From industry to agriculture, our Standard Series chains are designed to fit a wide variety of standard applications, and to last longer than any other manufacturer’s chain.

[Please login to see price]

Ask Quote

Ask Quote

Call us

SIT

- HTD pulleys have a different design from the traditional toothed pulleys. The axial grooves are designed to allow the beltteeth to catch the pulley teeth with negligible triction. HTD Pulleys are available with full hub and for assembly with SER-SIT taper bushing.

- Product detail :

- Type of belt : 14 M

- Pitch : 14 mm

- Pitch diameter : 246.76 mm

- Outside diameter + flange : 261 mm

- Teeth : 56

- Type of bush : 3535

- Belt width : 85 mm

- Type of pulley :2

- Material : Cast iron

- Flange : With flanges

[Please login to see price]

Ask Quote

Ask Quote

Call us

SIT

PBT Pulleys - for mounting taper bushing SER-SIT

Material: cast iron DIN 1691 GG-20/GG25

Finishing: protective surface treatment.

V-groove pulleys suitable for use with the following belts:

-SPZ-Z-3V

-SPA-A

-SPB-B-5V

-SPC-C

[Please login to see price]

Ask Quote

Ask Quote

Call us

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Call us

DIAMOND

Built to ASME / ANSI B29.1 standards for dimensions, interoperability, and sprocket fit, the ASME / ANSI Standard Roller Chain series also meets Diamond Chain’s rigorous internal requirements. From industry to agriculture, our Standard Series chains are designed to fit a wide variety of standard applications, and to last longer than any other manufacturer’s chain.

[Please login to see price]

Ask Quote

Ask Quote

Call us

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Call us

SIT

- Type of belt : 14 M

- Pitch : 14 mm

- Pitch diameter : 318.06 mm

- Outside diameter + flange : -

- Teeth : 72

- Belt width : 85 mm

- Type of pulley : 11

- Material : Cast iron

- Flange : Without flanges

[Please login to see price]

Ask Quote

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Call us

SIT

- SIT TAPER LOCK BUSHING is designed to give the following:

- 1. Perfect assembly

- 2. rapid dismantling of the pulley and other transmission equipment

- 3. No special tools requirement except hexagonal key

- The large range of finished bores available ensures that an immediate assembly can be made thus avoiding costly factory down-time.

- Here are the dimensions of Taper Bushing with type 2517 (65.45)

- - Bore : we provide taper bushing with minimal bore 16 mm and 3/4 inches; for the max bore you can look at the number writen after "BC" in every product name.

- for example, BC6545F16 (2517X16MM), so the max bore is 65 mm.

- - Width : the numbers writen in every product name before "F" is width size.

- for example, BC6545F16 (2517X16MM), so the width is 45 mm.

- - Bore size : look at the last number in every product name.

- for example, BC6545F16, so the bore size is 16.

[Please login to see price]

Ask Quote

Ask Quote

Call us

SIT

- Type of belt : 14 M

- Pitch : 14 mm

- Pitch diameter : 959.77 mm

- Outside diameter + flange : -

- Teeth : 216

- Type of bush : 4040

- Belt width : 85 mm

- Type of pulley :14

- Material : Cast iron

- Flange : Without flanges

[Please login to see price]

Ask Quote

Ask Quote

Call us

SIT

- HTD pulleys have a different design from the traditional toothed pulleys. The axial grooves are designed to allow the beltteeth to catch the pulley teeth with negligible triction. HTD Pulleys are available with full hub and for assembly with SER-SIT taper bushing.

- Product detail

- Type of belt : 8 M

- Pitch : 8 mm

- Pitch diameter : 227.81 mm

- Outside diameter + flange : -

- Teeth : 90

- Type of bush : 3020

- Belt width : 85 mm

- Type of pulley : 7

- Material : Cast iron

- Flange : Without flanges

[Please login to see price]

Ask Quote

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Call us

Ask Quote

Call us

SIT

- Type of belt : 14 M

- Pitch : 14 mm

- Pitch diameter : 371.54 mm

- Outside diameter + flange : -

- Teeth : 84

- Belt width : 85 mm

- Type of pulley : 11

- Material : Cast iron

- Flange : Without flanges

[Please login to see price]

Ask Quote

Ask Quote

Call us

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Call us

SIT

- Type of belt : 8 M

- Pitch : 8 mm

- Pitch diameter : 426.42 mm

- Outside diameter + flange : -

- Teeth : 168

- Type of bush : 3030

- Belt width : 85mm

- Type of pulley :14

- Material : Cast iron

- Flange : Without flanges

[Please login to see price]

Ask Quote

Ask Quote

Call us

[Please login to see price]

Ask Quote

Ask Quote

Call us

[Please login to see price]

Ask Quote

.png)