Sort By

All Category Groups

All Brands

All Categories

All Products 23965

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Available

[Please login to see price]

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Available

Special Order / Size Chain

JOHN KING

[Please login to see price]

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Ask Quote

Available

[Please login to see price]

Ask Quote

Ask Quote

Ask Quote

Available

[Please login to see price]

Ask Quote

Ask Quote

Available

STARKZ

Sprocket for chain according to DIN 8187 - ISO/R 606

De : External Diameter mm

Dp : Pitch Diameter mm

Dm : Hub Diameter mm

W : Weight kg

[Please login to see price]

Ask Quote

Ask Quote

Available

SIT

- TRASCO® ES is our zero backlash coupling designed to compensate for misalignment and vibration dampening for indexing applications. The compact design of TRASCO® ES makes it the right choice for all precise motion applications.

- This type of coupling premits quick, sure fixing, without any shaft-hub backlash.

- Product detail

- Outside diameter : 55 mm

- Max bore : 28 mm

- Material : Aluminum

- The M coupling type is available with or without keyway.

- Approved according to EC standard ATEX 94/9/EC.

[Please login to see price]

Ask Quote

Ask Quote

Available

Ask Quote

Available

SIT

Sprocket for chain according to DIN 8187 - ISO/R 606

De : External Diameter mm

Dp : Pitch Diameter mm

Dm : Hub Diameter mm

W : Weight kg

[Please login to see price]

Ask Quote

Ask Quote

Available

SIT

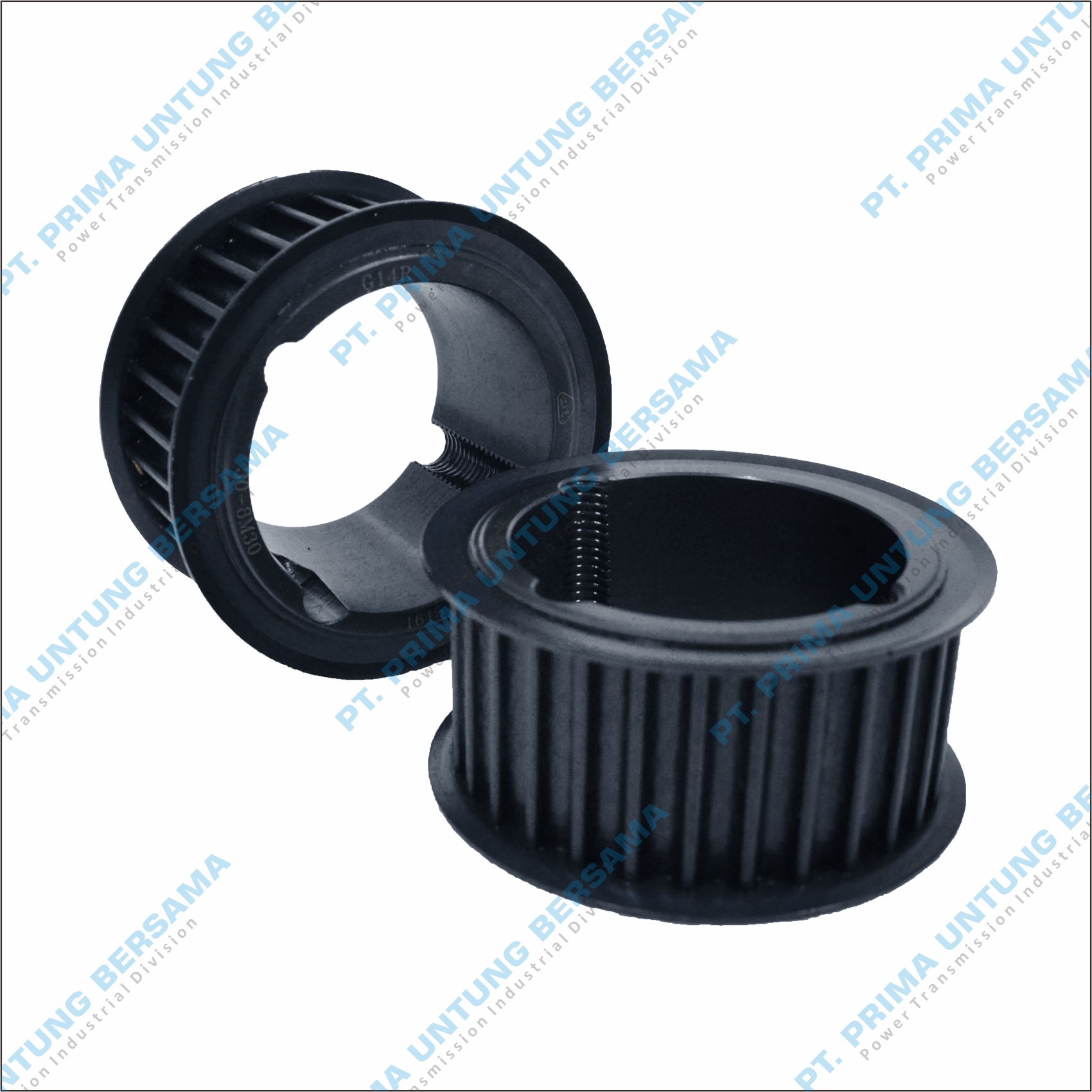

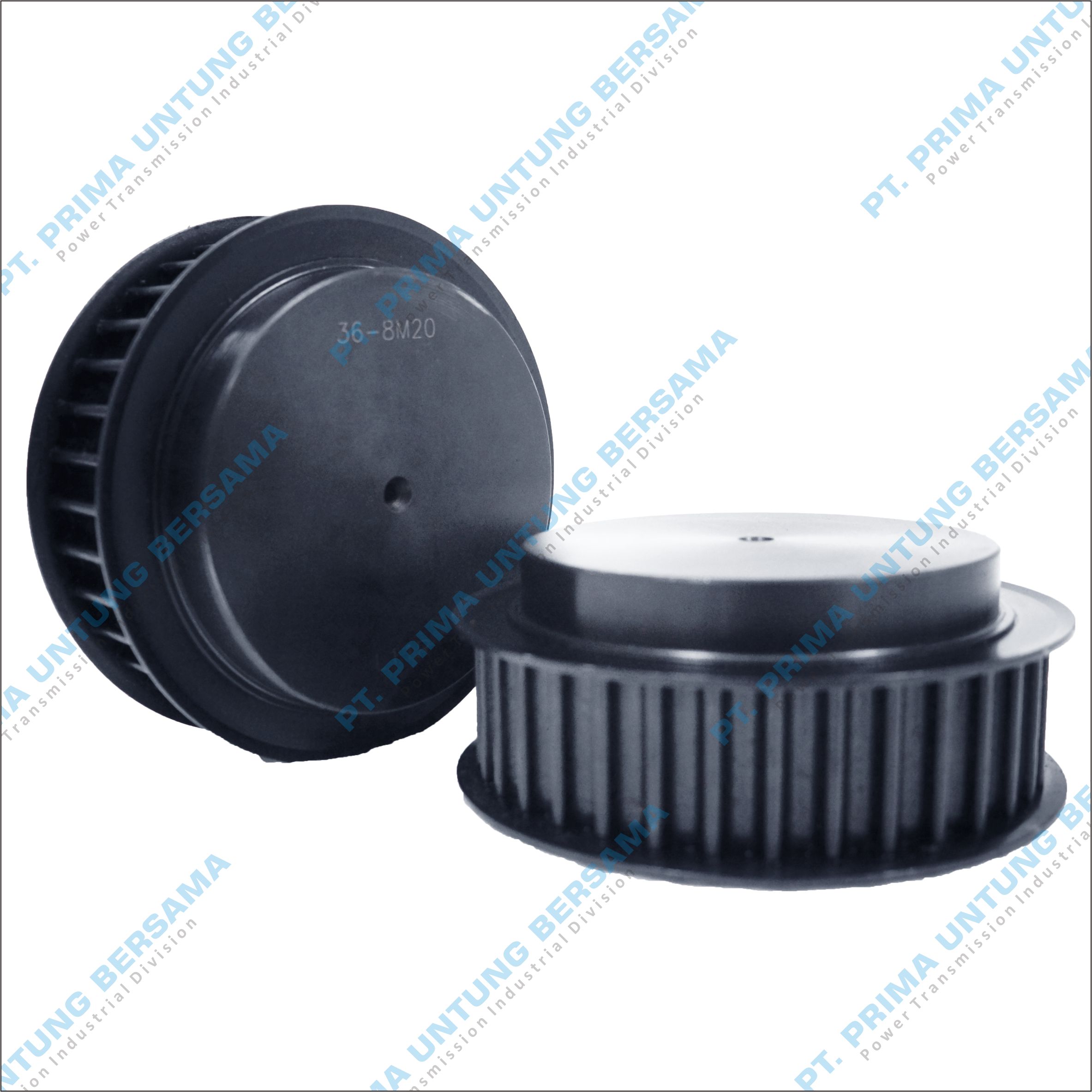

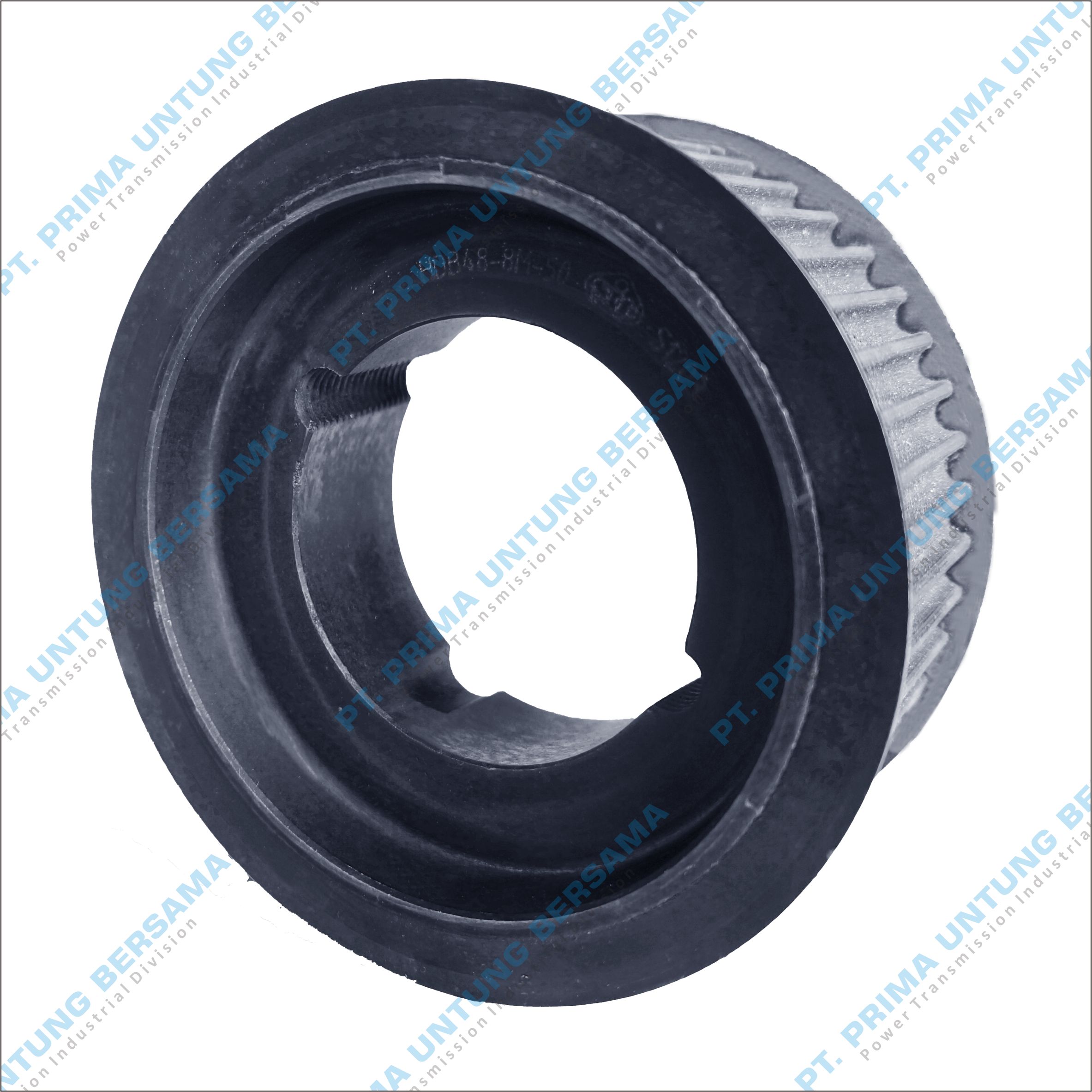

- HTD pulleys have a different design from the traditional toothed pulleys. The axial grooves are designed to allow the beltteeth to catch the pulley teeth with negligible triction. HTD Pulleys are available with full hub and for assembly with SER-SIT taper bushing.

- Product detail :

- Type of belt : 8 M

- Pitch : 8 mm

- Pitch diameter : 75.02 mm

- Outside diameter + flange : 84 mm

- Teeth : 50

- Type of bush : 1615

- Belt width : 50 mm

- Type of pulley :4

- Material : Cast iron

- Flange : With flanges

[Please login to see price]

Ask Quote

Ask Quote

Available

SIT

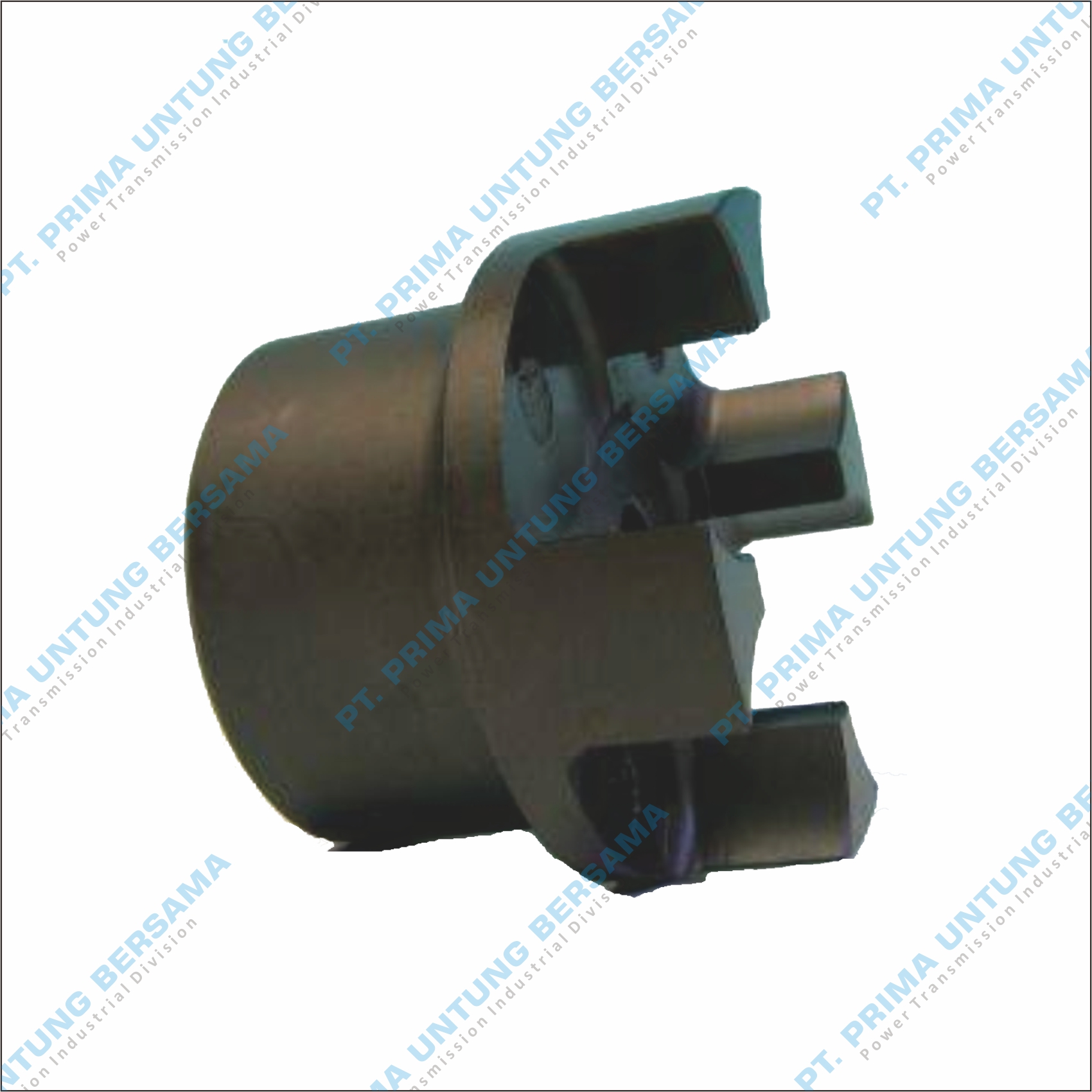

- TRASCO® couplings are dimensionally manufactured to hub types "A" and "B", the difference being the maximum shaft diameter which hubs can accpet (corresponding respectively to the first and second code number). The long hub execution "L" (allows full coverage of the motor shaft) is available in both "A" and "B" execution.

- Product detail

- Outside diameter : 95 mm

- Max bore : 55 mm

- Length : 246 mm

- Material : Cast iron grade GG25

- Approved according to EC standard ATEX 94/9/EC

[Please login to see price]

Ask Quote

Ask Quote

Available

[Please login to see price]

Ask Quote

Ask Quote

Available

Ask Quote

Ask Quote

Available

STARKZ

- POWERLOCK locking assembly unit consists of four pieces with two inside double-one rings joined through a set of tightening screws. It is recomended for medium torques. Although it is not self centering, it can be easily assembled and diassembled.

- Inner Diameter : 80 mm

- Outside Diameter : 120 mm

- High : 28 mm

- Screws : 14

- Type of Screws : M10

[Please login to see price]

Ask Quote

Ask Quote

Available

SIT

- TRASCO flexible couplings is the flexible and omocinetic coupling that assures the best performance in relation to the physical space occupied in its class. It has a very compact design and allows safe power transmision by absorbing peak loads and torsional vibrations.

- Product detail

- Outside diameter : 290 mm

- Max bore : 145 mm

- Material : Cast iron grade GG25

- Approved according to EC standard ATEX 94/9/EC

[Please login to see price]

Ask Quote

Ask Quote

Available

STARKZ

Sprocket for chain according to DIN 8187 - ISO/R 606

De : External Diameter mm

Dp : Pitch Diameter mm

Dm : Hub Diameter mm

W : Weight kg

[Please login to see price]

Ask Quote

Ask Quote

Available

JOHN KING

No description for this product yet.

[Please login to see price]

Ask Quote

Ask Quote

Available

SIT

- Type of belt : AT10

- Pitch : 10 mm

- Pitch diameter : 68.15 mm

- Outside diameter + flange: 73 mm

- Teeth : 22

- Belt width : 25 mm

- Type of pulley : 2

- Material : Aluminium

[Please login to see price]

Ask Quote

Ask Quote

Available

SIT

- High speed precision joints with needle roller bearings series "H"(DIN 808)

- - Roller bearings lubricated for life. No maintenance required.

- - Precise and versatile, silent and smooth running; wide application field.

- - Max. angel : 45° type "H",90° type "HD", max. speed 4.000 rpm.

- - Special executions upon request.

- Here are the dimension of product :

- Outside diameter : 80 mm

- Inner diameter : 40 mm

- Length of half joint : 80 mm

- Full length : 160 mm

[Please login to see price]

Ask Quote

Ask Quote

Available

STARKZ

- Inner Diameter : 60 mm

- Outside Diameter : 90 mm

- High : 33 mm

- Screws : 8

- Type of Screws : M8

[Please login to see price]

Ask Quote

Ask Quote

Available

SIT

- Our pulleys can be used for application with a speed up to 35m/s. The pulley dimensions are very accurate as they are manufactured only by means of CNC or automatic lathes.

- For higher speed is strongly recomended to use steel as material of construction. Our PBT pulleys are satically balanced according to ISO.

- The PT pulleys are not balanced, as they do not have a finished bores.

- Here are the dimensions of "PBT" SPZ with taper bush 1108 :

- - Belt type : SPZ

- - Taperbush : 1108

- - Shaft diameter range : 11 - 28 mm

- - Pitch diameter : refer to numbers writen after "PBT" in every product name.

- For example, product name : PBT063SPZ2 (1108); so, the pitch diameter is 63 mm

- - Outside diameter : you can add the pitch diameter with 4 to know the length of outside diameter.

- For example, the product is PBT063SPZ2 (1108); so the outside diameter is 63 + 4 = 67 mm

- - Groove : refer to the last number in every product name.

- For example for PBT063SPZ2; so, the groove is 2

- See recomendation taperbush below.

[Please login to see price]

Ask Quote

Ask Quote

Available

STARKZ

Sprocket for chain according to DIN 8187 - ISO/R 606

De : External Diameter mm

Dp : Pitch Diameter mm

Dm : Hub Diameter mm

W : Weight kg

[Please login to see price]

Ask Quote

Ask Quote

Available

STARKZ

- Inner Diameter : 110 mm

- Outside Diameter : 155 mm

- High : 44 mm

- Screws : 8

- Type of Screws : M12

[Please login to see price]

Ask Quote

Ask Quote

Available

[Please login to see price]

Ask Quote

Ask Quote

Available

SIT

- TOP DRIVE® HTD belt is an evolution of standard positive drive belts. The tooth shape is the HTD profile according to ISO 13050.

- This profile has been used for many years in a wide range of applications and it is well known for its outstanding performances. Power transmission is much higher compared to the classic inch trapezodial profile.

- The circular-arc tooth provides superior tooth jump resistance and provides a smooth tooth engagement. The noise level is remarkably reduced if compared to the classic trapezodial belts.

- How to measure the size of a product :

- For example, CHD1064-8M20

- - 1640 = pitch length (mm)

- - 8M = pitch

- - 20 = belt width (mm)

[Please login to see price]

Ask Quote

Ask Quote

Available

SIT

- Type of belt : H

- Pitch : 12700 mm

- Pitch diameter : 95.65mm

- Outside diameter + flange: 104 mm

- Teeth : 24

- Type of bush : 1610; max bore : 42 mm

- Belt width : 1.00 inch

- Type of pulley : 4

- Material : Cast iron

- Flange : With flange

[Please login to see price]

Ask Quote

Ask Quote

Available

DIAMOND

standard connecting links are used when roller chains are operated under normal conditions. for severe applications, press fit connecting links are suggested.

[Please login to see price]

Ask Quote

.png)

.jpg)

.png)

.png)